REDUCE THE CARBON FOOTPRINT

THE SOLUTION TO BRINE DISCHARGE

Land-based desalination plants always discharge brine in the same place, which has the effect of upsetting the eco-system.

Our ship discharges brine in its wake, and always when the ship is underway, so never in the same place and in deep water.

Our solution therefore desalinizes less than natural evaporation.

Power consumption for desalination is integrated into the ship’s electrical management system.

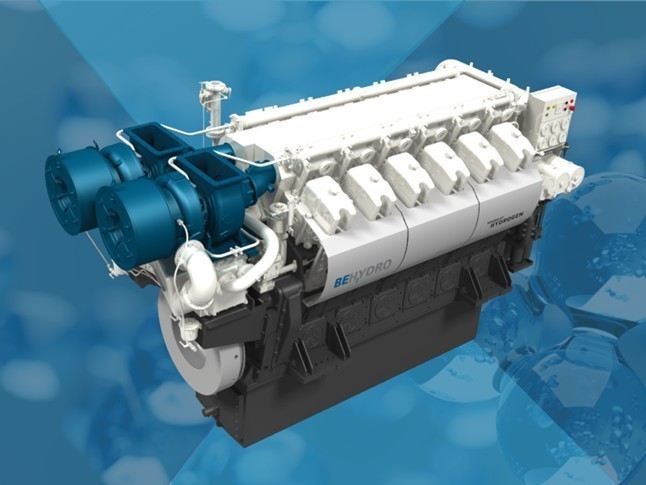

Hydrogen Engines

The BEH2YDRO dual-fuel engines are developed for heavy-duty applications and are very flexible in usage. Operating on 85% hydrogen gas and 15% conventional fuel, they make the owner or user less dependent on fossil fuels.

The BEH2YDRO dual-fuel hydrogen engines use proven technology, have been extensively tested and they are certified. They are designed to ensure long-term and efficient operation. These engines are available with 6 or 8 cylinders in line and 12 or 16 cylinders in V and deliver power from 1,000 up to 2,670 kW. In addition, as auxiliary generators, they provide a reliable and environmentally friendly source of energy for ships, drilling rigs or other marine applications when combined with an alternator.

The majority of large port cities were established to provide vital access to the sea. Now, more than ever, ports are a driving force for economic development, international trade, and cultural exchange.

However, ports are often perceived by the local community as a nuisance — especially in terms of pollution. Of particular concern is the pollution generated by ships at berth, which has become unacceptable to today’s environmentally aware citizens.

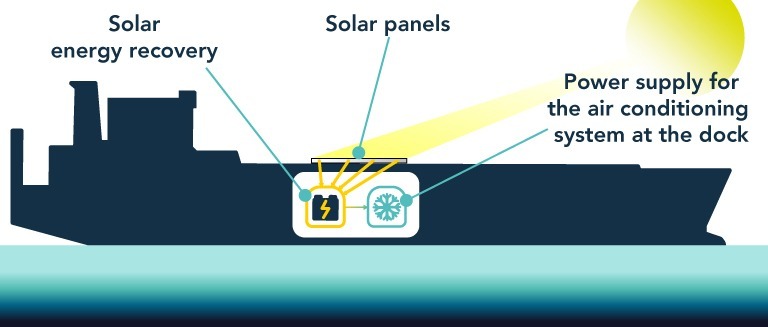

Solar energy

Equipping ships with nearly 1500m² of solar panels. Batteries ins- talled on board and charged by solar energy will provide at least a complete autonomy of one day in port.

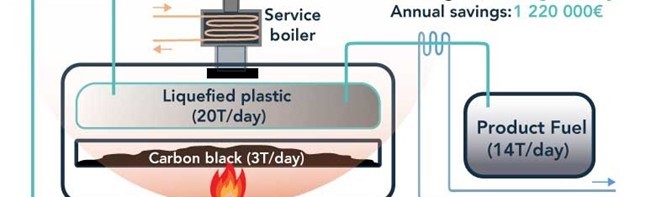

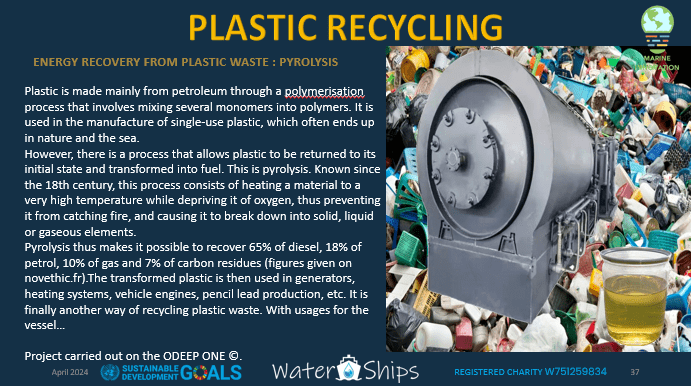

Pyrolysis

Recycling plastic into ship’s fuel. Conversion of 20 tons of plastic per day into 14 tons of fuel via energy self-sufficient pyrolysis. Non-recyclable plastic provided by local NGOs

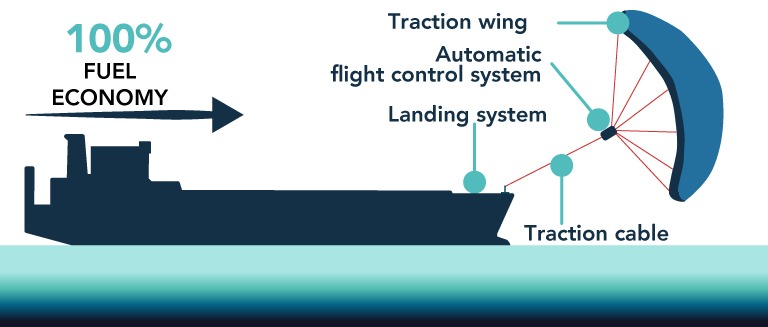

Kite Sail

During production, a 500m² kite sail allows to move forward at a speed of 3 knots, without using the engines thereby reducing emissions – during the 5 days of production.

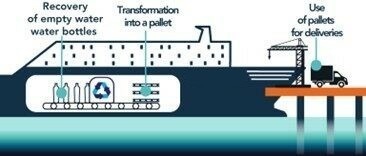

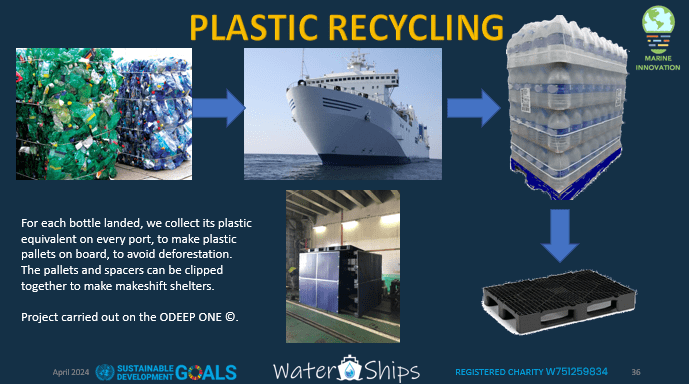

Plastic Recycling.

Supplying wooden pallets for logistics is often not the optimal so- lution. Heavier than plastic and often imported, they degrade the carbon footprint. With the objective of “as much PET in, as much PET out”, the recycling of plastic into pallets is beneficial ecologically and economically

Bio-Sourced

Towards a bio-sourced plastic for in- dustrial use.

The R&D, in association with start-ups, aims to

develop a bio-sourced bottle based on marine algae.

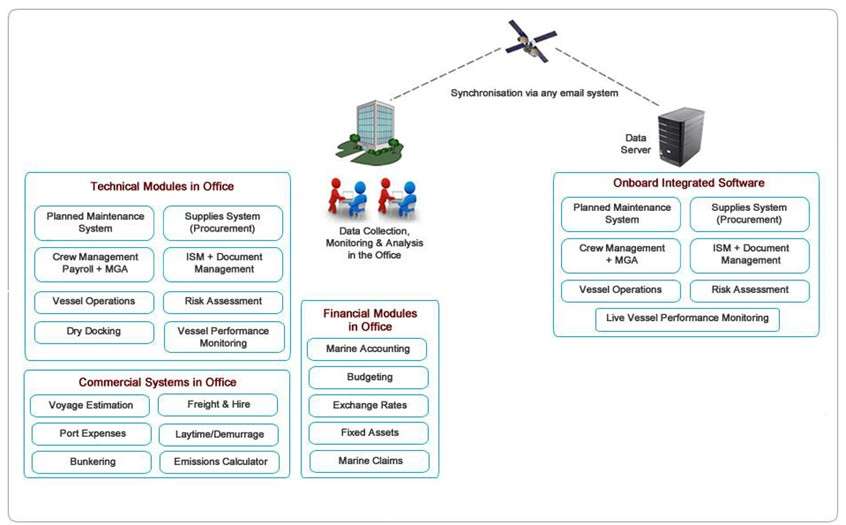

The “SEAHORSE MANAGER” software suite provides technical, production and human resources management.